The woodworking industry has always been on the lookout for ways to improve efficiency and precision. One of the key areas of focus has been the horizontal woodworking band saw, a crucial tool for any woodworking workshop. This machine, which uses a continuous band of metal with teeth along one edge to cut various types of wood, has been around for years. However, with the advancement in technology, there has been a significant improvement in its operation, thanks to the use of frequency converters like the SKI90 Inverter.

The use of a frequency converter in a horizontal woodworking band saw helps in controlling the speed of the saw blade, thereby enhancing the quality of the cut and reducing wastage. The SKI90 Inverter, for instance, allows for the precise control of the motor speed, which in turn controls the speed of the saw blade. This ensures that the blade moves at the optimum speed for the type of wood being cut, resulting in a smoother finish and less waste.

Now that we have established the importance of using a frequency converter in a horizontal woodworking band saw, let's delve deeper into how it works and the benefits it offers.

What is a Woodworking Band Saw?

A woodworking band saw is a power tool designed to cut wood with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels. It is commonly used in woodworking for its ability to make precise cuts, even in intricate or irregular shapes. The band saw blade moves in a continuous loop, allowing for smooth and uniform cuts.

The horizontal woodworking band saw specifically refers to the band saw where the workpiece is fed into the blade horizontally. It is consists of a circular saw blade tensioned between two wheels. The circular saw blade is driven by an electric motor through the wheels, performing continuous cutting motion. The feed of the wood can be done manually or automatically using a conveyor or roller.

This tool is essential for various woodworking applications, including cutting curves, resawing, and ripping lumber.

How Does a Frequency Converter Work in a Woodworking Band Saw?

A frequency converter, also known as a variable frequency drive (VFD), is a device that converts the electrical power supply's frequency and voltage to match the requirements of the electric motor. The SKI90 Inverter, for example, converts the incoming AC power to DC and then inverts it back to a variable frequency and voltage AC power. This allows for the precise control of the motor speed and, consequently, the speed of the saw blade.

The woodworking band saw consists of a circular saw blade tensioned between two wheels. The circular saw blade is driven by an electric motor through the wheels, performing continuous cutting motion. The feed of the wood can be done manually or automatically using a conveyor or roller. By using a frequency converter like the SKI90 Inverter, the speed of the electric motor, and hence the speed of the saw blade, can be precisely controlled. This ensures that the blade moves at the optimum speed for the type of wood being cut, resulting in a smoother finish and less waste.

What Are the Benefits of Using a Frequency Converter in a Woodworking Band Saw?

Using a frequency converter in a woodworking band saw offers several benefits:

- Improved Cut Quality: Controlling the speed of the saw blade ensures that it moves at the optimum speed for the type of wood being cut. This results in a smoother finish and less chipping or splintering of the wood.

- Reduced Waste: Precise control of the saw blade speed reduces the chances of the blade binding or drifting, which can lead to waste. Additionally, a smoother cut means less sanding is required, further reducing waste.

- Energy Savings: A frequency converter only supplies the motor with the power it needs at any given moment, thereby reducing energy consumption. This can lead to significant cost savings over time.

- Extended Blade Life: Operating the saw blade at the optimum speed reduces wear and tear on the blade, thereby extending its life.

- Improved Operator Safety: A frequency converter allows for the soft start of the motor, reducing the mechanical stress on the motor and the rest of the machine. This also reduces the risk of injury to the operator.

How is SAKO Frequency Converter SKI90 performance on a Woodworking Band Saw?

1.The working process is as follows:

The trolley worktable runs at a certain speed for a distance, this speed is usually slow, and the PLC gives the frequency converter start and multi-speed signals.

The frequency converter drives the trolley worktable motor to move at a low speed. When the saw blade is about 5 centimeters from the wood, the PLC gives the frequency converter a high-speed signal to increase the speed of the worktable. Once the saw blade reaches the end of the wood, the saw frame rises a certain distance, and the worktable slows down and returns to its original position. This process is controlled by the PLC giving on/off signals, and the frequency converter executes multi-speed operation.

The process requires that the trolley of the equipment can be selected to run automatically or manually.

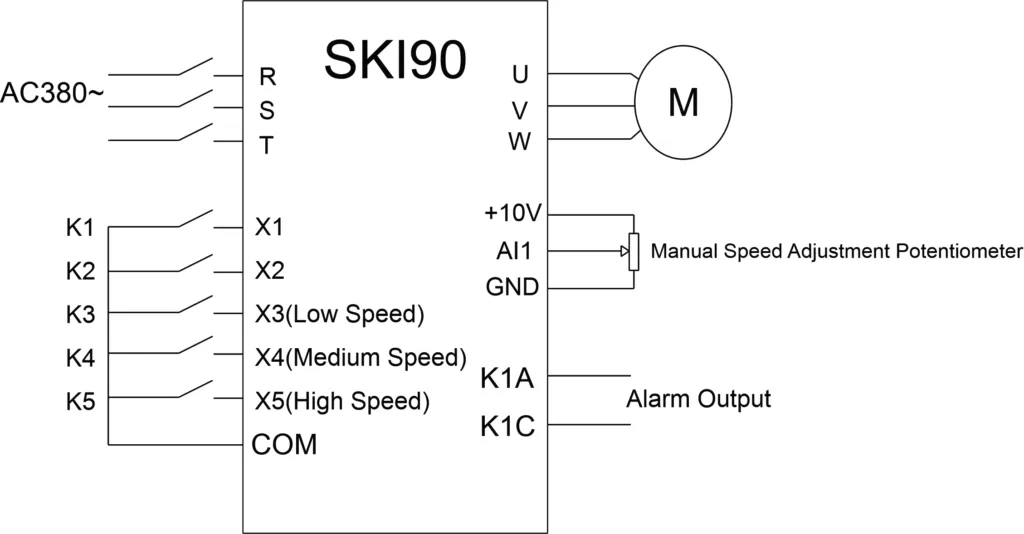

2.Frequency Converter (SKI90) Wiring Diagram

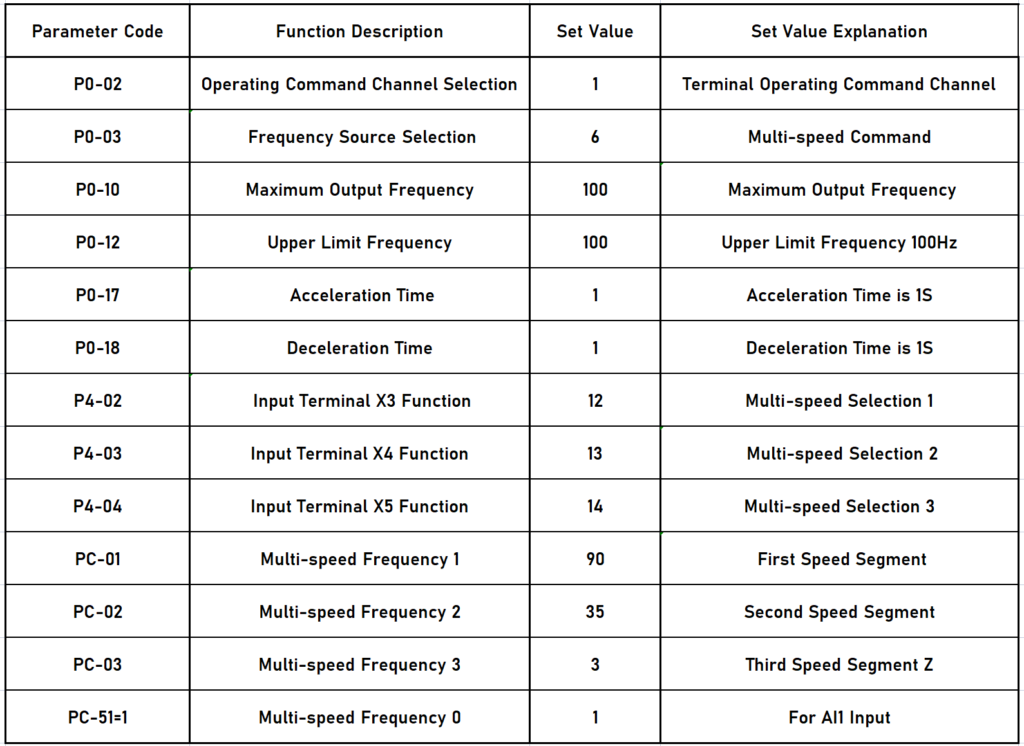

3.Frequency Converter(SKI90) Parameter Setting

SAKO SKI90 Frequency Converter Technical Features

The SAKO SKI90 series frequency converter is a high-performance vector frequency converter based on DSP (Digital Signal Processing), achieving high-speed, high-performance control.

By controlling the motor's magnetic flux current, it enables rapid response and accurate control of the motor, allowing for high-precision, wide-range speed operation and control.

There are up to 10 ways to set the frequency, and the maximum output frequency can reach 3000HZ. Moreover, it can be switched in various ways through A frequency source selection and B frequency source selection. Three start-up methods can be chosen based on different equipment processes. The steady-speed accuracy can reach up to or less than 0.5% of the rated synchronous speed, and the speed control stability can reach up to or less than 0.2% of the rated synchronous speed. There are up to 5 V/F curves, and the unique multi-point V/F curve makes the torque increase more stable and efficient.

Conclusion

The use of a frequency converter in a horizontal woodworking band saw is crucial for improving the quality of the cut, reducing waste, and saving energy. The SKI90 Inverter, with its precise control of motor speed, offers a reliable and efficient solution for woodworking professionals. Investing in a frequency converter for your woodworking band saw is not only a smart business decision but also a step towards creating a safer and more sustainable working environment.