We all know that water is a precious resource, but sometimes, we just need it gone – and fast. Whether it’s removing surface water from a construction site or draining water from a basement after a heavy rainfall, efficient water removal is essential. This is where the automatic drainage system comes into play.

Automatic drainage systems are designed to remove water from specific areas quickly and efficiently. A crucial component of these systems is the frequency converter, which plays a vital role in regulating the motor speed of the drainage pumps, thus optimizing the performance of the drainage process.

The ability to manage the water drainage process effectively can be a lifesaver, especially during the rainy season or in flood-prone areas.

How Does Frequency Converter Help?

A frequency converter is a device that converts the power frequency of the electric energy supplied to the motor. In an automatic drainage system, the motor’s speed and torque needs to be controlled accurately to ensure that the water is drained efficiently without overloading the system.

The motor speed is directly proportional to the frequency of the electrical supply. By changing the frequency of the electrical supply to the motor, the speed of the motor, and hence the pump, can be controlled. This is where the function of the frequency converter comes into play.

Using a frequency converter in the automatic drainage system allows us to control the pump and fan’s speed remotely or automatically, depending on the water level. This ensures that the pump operates at its most efficient point, saving energy and reducing wear and tear on the pump.

Why Is It Important?

In many areas around the world, flooding is a common occurrence, causing significant damage to property and infrastructure.

It’s not just the initial flooding that causes problems, but the standing water that remains after the floodwaters have receded. This standing water can cause health issues, damage to buildings and infrastructure, and provide a breeding ground for insects and other pests.

An efficient drainage system is essential to remove this water quickly and prevent these problems. The use of a frequency converter in the drainage control system allows us to optimize the pump’s operation, ensuring that the water is removed as quickly and efficiently as possible.

How Does It Work?

The frequency converter is connected to the motor of the drainage pump. The converter adjusts the frequency of the electrical supply line to the motor, thus controlling its speed.

A sensor is placed in the area to be drained, which sends signals to the frequency converter, indicating the water level. The frequency converter then adjusts the motor speed accordingly. For example, if the water level is high, the frequency converter will increase the motor speed to drain the water quickly. Conversely, if the water level is low, the motor speed will be reduced to save energy.

The frequency converter can also be programmed to operate the pump at specific times or under certain conditions. For example, it can be programmed to start the pump when the water level reaches a certain point and stop it when the water level drops below a specified level.

What Are The Benefits?

Optimal Pump Operation: The frequency converter regulates the speed of the pump motor by adjusting the frequency of the electrical supply. This enables the pump to operate at different speeds based on the water level, ensuring that the pump operates at its most efficient point. For example, when the water level is high, the frequency converter will increase the motor speed to drain the water quickly. Conversely, if the water level is low, the motor speed will be reduced to save energy.

Energy Savings: By operating the pump at its most efficient point, the frequency converter helps save energy. This not only contributes to environmental conservation but also helps reduce the operational costs of the drainage system.

Preventing Pump Damage: Operating the pump at excessive speeds can lead to wear and tear, and ultimately damage the pump. The frequency converter helps in preventing this by regulating the motor speed and ensuring that the pump does not operate at excessive speeds.

Flexibility: The frequency converter can be programmed to operate the pump under specific conditions, providing flexibility in the operation of the drainage system. For example, it can be programmed to start the pump when the water level reaches a certain point and stop it when the water level drops below a specified level.

Quick Response: The use of sensors to monitor the water level allows the system to respond quickly to changes in water level, ensuring that the water is removed quickly and efficiently.

Remote Monitoring and Control: The use of a frequency converter enables remote monitoring and control of the pump operation. This eliminates the need for personnel to be on-site to monitor the equipment operation, and allows for automatic operation based on the pre-set liquid levels.

The Application of SKI90 Frequency Converter in Automatic Drainage System

The SKI90 Frequency Converter, combined with the Kunlun Tongtai touch screen, uses liquid level sensors to automatically detect the water level and other parameters in a well.

Based on the water level, it can efficiently manage the operation of the water pumps, achieving full automatic control of the mine drainage system.

This not only helps in saving human resources but also contributes to energy conservation by peak shaving and valley filling. Hence, it has considerable value for widespread application.

Working Principle:

The liquid level sensor detects the liquid level height and feeds it back to the touch screen, which then controls the voltage and the frequency of the frequency converter based on the system parameters.

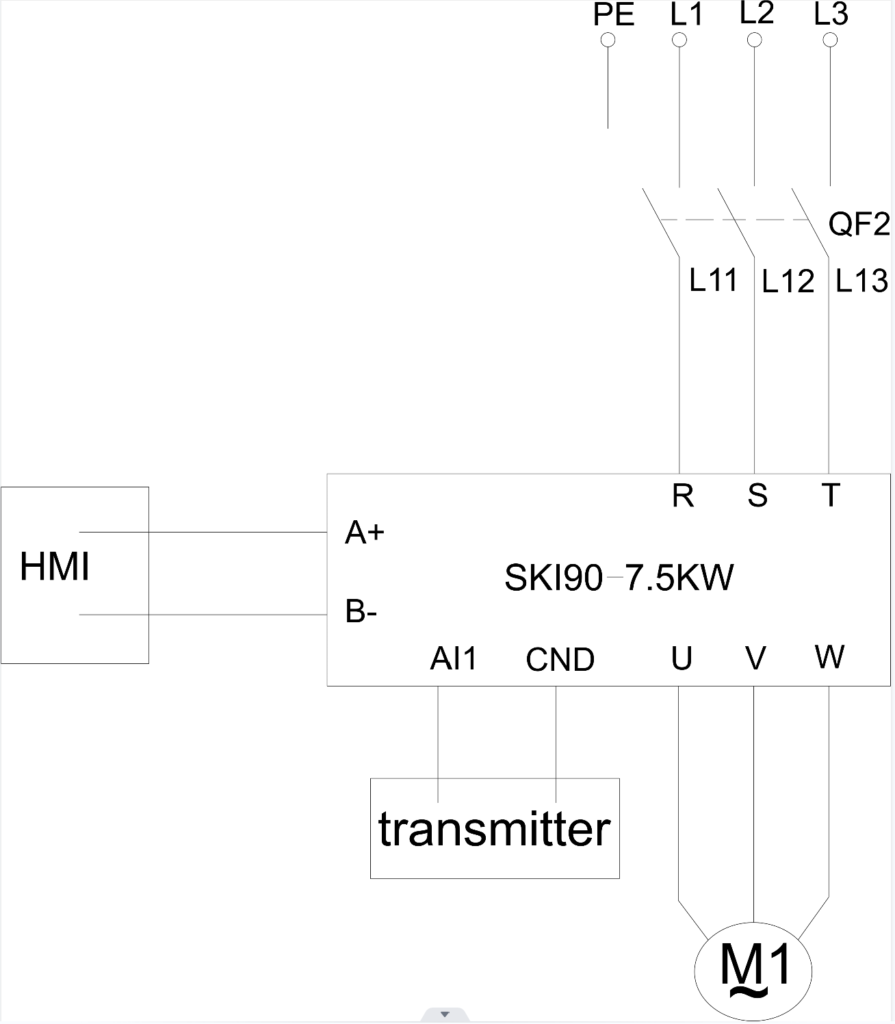

Wiring Diagram of the Drainage System:

Advantages of the Solution:

After the equipment modification, the MHI+SKI90 frequency converter unit is used for control, making the data straightforward and the setup simple. There is no need for personnel to monitor the equipment operation on-site; it will work automatically based on the pre-set liquid levels.

Abandoning traditional drainage methods not only allows for control of the liquid level but also reduces electricity usage and increases water resource utilization.

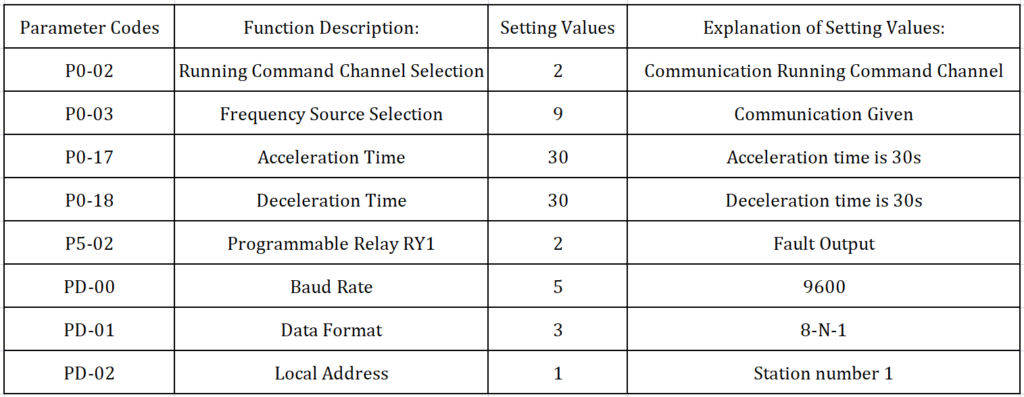

Parameter Settings:

Advantages of the Solution

The pressure of water in the heating networks is crucial for the stability of all systems. In real use the old phenomena of pipe network systems of user pipes have risen in prevalence and these factors cause the instability in pipe network pressure.

In the earlier years, electricity contact and various techniques were utilized to control the water makeup pump for makeup. The pump is poor in control accuracy and high frequency power start current. It is possible to resolve this problem using frequency converter control for automatic water replenishment systems.

System Parameters

Water Liquid Level: When the water level is below this level, the water pump stops: This prevents damage to the water pump and saves energy.

Hysteresis: When the water level is higher than (low water level + hysteresis), the water pump brake opens and starts working.

1# Liquid Level, 1# Frequency: When it reaches the 1# liquid level, it operates at 1# frequency.

2# Liquid Level, 2# Frequency: When it reaches the 2# liquid level, it operates at 2# frequency.

3# Level Value, 3# Frequency: When it reaches the 1# liquid level, it operates at 1# frequency.

4# Liquid Level, 4# Frequency: When it reaches the 1# liquid level, it operates at 1# frequency.

Upper Limit Alarm: An alarm is triggered when the water level reaches the upper limit.

Maintenance and Troubleshooting

Regular maintenance of an automatic drainage system using a frequency converter is crucial for its optimal functioning.

The maintenance activities usually involve checking the sensors for any dirt or debris that might affect their accuracy, ensuring that the wiring and connections are in good condition, and checking the pump and motor for any signs of wear and tear.

Additionally, the frequency converter itself should be checked for any issues, such as overheating or abnormal noises. Common troubleshooting issues might include the system not responding to changes in water level, the pump not operating at the correct speed, or the frequency converter not responding to commands. These issues could be due to a variety of reasons, such as a faulty sensor, a problem with the wiring, or a malfunctioning frequency converter. It is essential to have a well-documented troubleshooting guide that lists the common problems, their possible causes, and the steps to address them.

Regular maintenance and timely troubleshooting will ensure that the automatic drainage system operates efficiently and effectively, minimizing the risk of flooding and water damage.

For any maintenance needs, feel free to consult us.

Conclusion

The use of a frequency converter in an automatic drainage system offers several benefits, including energy savings, reduced wear and tear on the pump, and flexibility in the operation of the system. Additionally, it ensures a quick response to changes in water level, helping to remove water quickly and efficiently. This is especially important in flood-prone areas, where rapid water removal is essential to prevent damage to property and infrastructure.