When considering VFDs (Variable Frequency Drives), one of the first questions that comes up is: which types of motors can be used with them? Understanding motor compatibility is essential for optimizing your system’s performance and efficiency. So, which motors work best with a VFD?

VFDs are designed to work primarily with AC motors, especially induction motors, but with the right setup, they can also be used with other types of motors like synchronous and permanent magnet motors.

Let’s dive deeper into the types of motors that can be used with VFDs and the considerations to keep in mind when selecting a motor for your application.

What motors can be used with VFD?

A variety of motors can be used with VFDs, but AC motors, particularly induction motors1, are the most common. Other motors, such as synchronous motors2 and [permanent magnet motors3, can also be compatible under the right conditions.

AC induction motors are the most commonly used motors with VFDs because they are simple, cost-effective, and reliable for a wide range of applications.

VFDs work by controlling the frequency of the power supplied to the motor, which alters the motor’s speed. AC motors, which are designed to operate with alternating current, are ideally suited for VFDs because they can efficiently adjust their speed without causing excessive wear on the motor or system.

Why are induction motors ideal for VFDs?

[Induction motors]4(https://goemc.com/2021/02/04/vfds-pros-and-cons/ "Induction motors") are the most commonly used type of motor because they are rugged, efficient, and require minimal maintenance. A VFD controls the frequency of the AC power supplied to the motor, which in turn regulates the speed. This ability to vary the speed makes them perfect for many applications, such as pumps, fans, and conveyors.

Induction motors are relatively simple, inexpensive to manufacture, and require less maintenance than other motor types. VFDs work by altering the frequency of the power supplied to the motor, which directly influences the motor speed. This allows for more precise control over the motor’s output, leading to energy savings and improved system efficiency.

Can VFDs be used with other motor types?

While VFDs are most commonly used with AC induction motors, they can also be used with synchronous motors and permanent magnet motors, though each type requires a different setup. For example, [permanent magnet motors]5(https://www.se.com/us/en/faqs/FA282553/ "permanent magnet motors") often require a VFD that can handle the unique characteristics of the motor’s operation.

Permanent magnet motors, known for their high efficiency, are becoming increasingly popular, especially in industries looking to reduce energy consumption. These motors, however, require a more advanced VFD capable of controlling their speed with precision due to their design.

Can a general purpose motor be used with a VFD?

A [general-purpose motor]6(https://darwinmotion.com/blogs/what-types-of-motors-can-be-used-with-vfds#:~:text=Induction%20Motors%3A,precise%20speed%20control%20is%20required. "general-purpose motor") is usually a standard AC motor, and yes, it can be used with a VFD. These motors are versatile and commonly found in various industrial applications. But what makes them suitable for use with a VFD?

![General-purpose AC motors controlled by a VFD, with careful selection required to ensure optimal performance and efficiency.]

(

)

General-purpose motors are designed to handle a variety of tasks, and their simplicity makes them a good match for VFD control. The VFD can adjust the speed of the motor to match the load, resulting in better energy efficiency and less wear over time.

A general-purpose motor is typically used in less specialized applications. Examples include standard HVAC systems, fans, pumps, and small conveyor systems. These motors operate well with a VFD because they can adjust to varying speeds without negatively impacting performance.

Considerations for using a general-purpose motor with a VFD

- Motor Rating: Ensure that the motor’s voltage and current ratings are compatible with the VFD.

- Load Requirements: General-purpose motors work best with light to medium loads. If the load is too heavy or variable, special consideration should be given to motor and VFD compatibility.

Common applications for general-purpose motors

- Conveyors: Adjusting the speed based on production needs.

- Fans and Blowers: Varying the airflow according to system requirements.

- Pumps: Adjusting water or liquid flow based on operational demands.

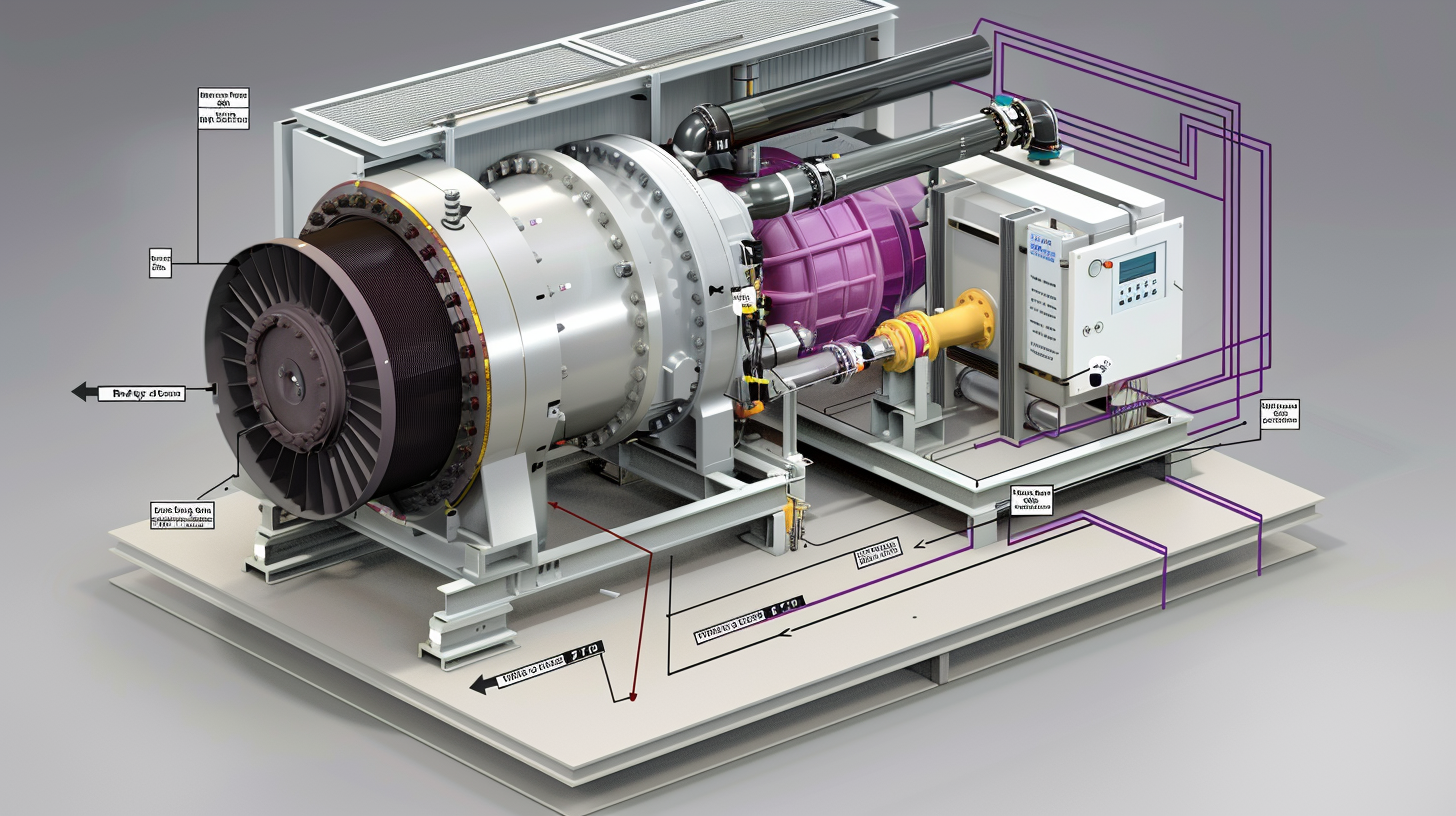

Which of the following motors does a variable frequency drive work with?

When selecting a motor for use with a VFD, it’s essential to understand which types of motors are compatible. In general, VFDs work with a wide range of motors, but some are more suitable than others. So, which motors are best for use with a VFD?

VFDs work best with AC motors, specifically induction motors, although they can also work with some synchronous and permanent magnet motors depending on the application.

(

))

)

- Induction Motors: These are the most common and widely used motors for VFDs.

- Synchronous Motors: Can also work with VFDs, though they require careful handling.

- Permanent Magnet Motors: Require specialized VFDs but can work very efficiently with precise control.

Key differences in motor types:

- Induction Motors: Easy to control with a VFD, widely available, and cost-effective.

- Synchronous Motors: Require more precise speed control but can be compatible with VFDs.

- Permanent Magnet Motors: Offer high efficiency and precision but require specific VFDs to handle their unique characteristics.

Induction motors are the most commonly used motors with VFDs because of their simplicity and cost-effectiveness. They are ideal for applications where variable speed control is necessary but without requiring high precision or complexity. Synchronous motors and permanent magnet motors, while also compatible with VFDs, often require specialized VFDs for optimal performance.

Why are some motors not ideal for VFDs?

Not all motors can efficiently work with VFDs. Fixed-speed motors, such as certain types of DC motors, are typically not suited for variable speed control. DC motors, for example, require a different type of controller to manage speed.

Can you put a variable speed control on any motor?

While it might seem like any motor could work with a variable speed control (VSD)7 like a VFD, not all motors are designed for variable speed control. What factors should be considered before deciding to put a VSD on a motor?

Not all motors are suitable for variable speed control. Only motors designed to handle variable speeds, like AC induction and synchronous motors, should be used with VSDs.

Motors that are designed to run at a fixed speed are typically not suitable for variable speed control, as they are not built to handle the continuous adjustments required by a VSD. However, with some motors, such as those used in HVAC or conveyor systems, a VSD can be very effective in improving energy efficiency and performance.

Why can’t all motors use a VSD?

- Fixed-Speed Motors: These motors are designed to operate at a constant speed and cannot effectively respond to changes in frequency or voltage.

- DC Motors: While they can be controlled with a different type of controller, VSDs are typically used with AC motors.

Can a VSD be retrofitted to existing motors?

In many cases, VSDs can be retrofitted to existing motors, especially if the motor is compatible. Retrofitting a VSD offers the benefit of energy savings and improved control, but it requires ensuring that the motor is suited for variable speed operation. Retrofitting can be an effective solution for businesses looking to upgrade their systems without needing to purchase new motors.

Conclusion

When selecting a motor for use with a VFD, it’s essential to choose one that is designed for variable speed control, such as an AC induction motor, synchronous motor, or permanent magnet motor. General-purpose motors work well with VFDs, but proper matching of the motor and VFD is key to ensuring optimal performance. By understanding the compatibility and features of different motors, you can enhance system efficiency and reduce energy costs. Choosing the right motor can maximize the benefits of your VFD system and lead to a more efficient and cost-effective operation.

- Clicking this link would give the reader specific insights into why induction motors are ideal for use with VFDs, including their advantages and common applications. ↩

- This link would guide readers on the compatibility and operational differences of synchronous motors with VFDs, helping them decide if this type is suitable for their needs. ↩

- Offers detailed information on permanent magnet motors, known for their high efficiency, and the specific VFD capabilities required for their control. ↩

- Clicking this link will provide more technical insights into the working principle and benefits of AC induction motors, which are ideal for VFDs in most industrial applications. ↩

- Clicking this link helps readers learn about the specialized VFDs needed for permanent magnet motors, ensuring proper functionality and control. ↩

- This link will explain the various types of general-purpose motors and why they are commonly used in industrial applications with VFDs. ↩

- This link explains how Variable Speed Drives (VSDs) work and which types of motors are best suited for variable speed control applications. ↩