(

)

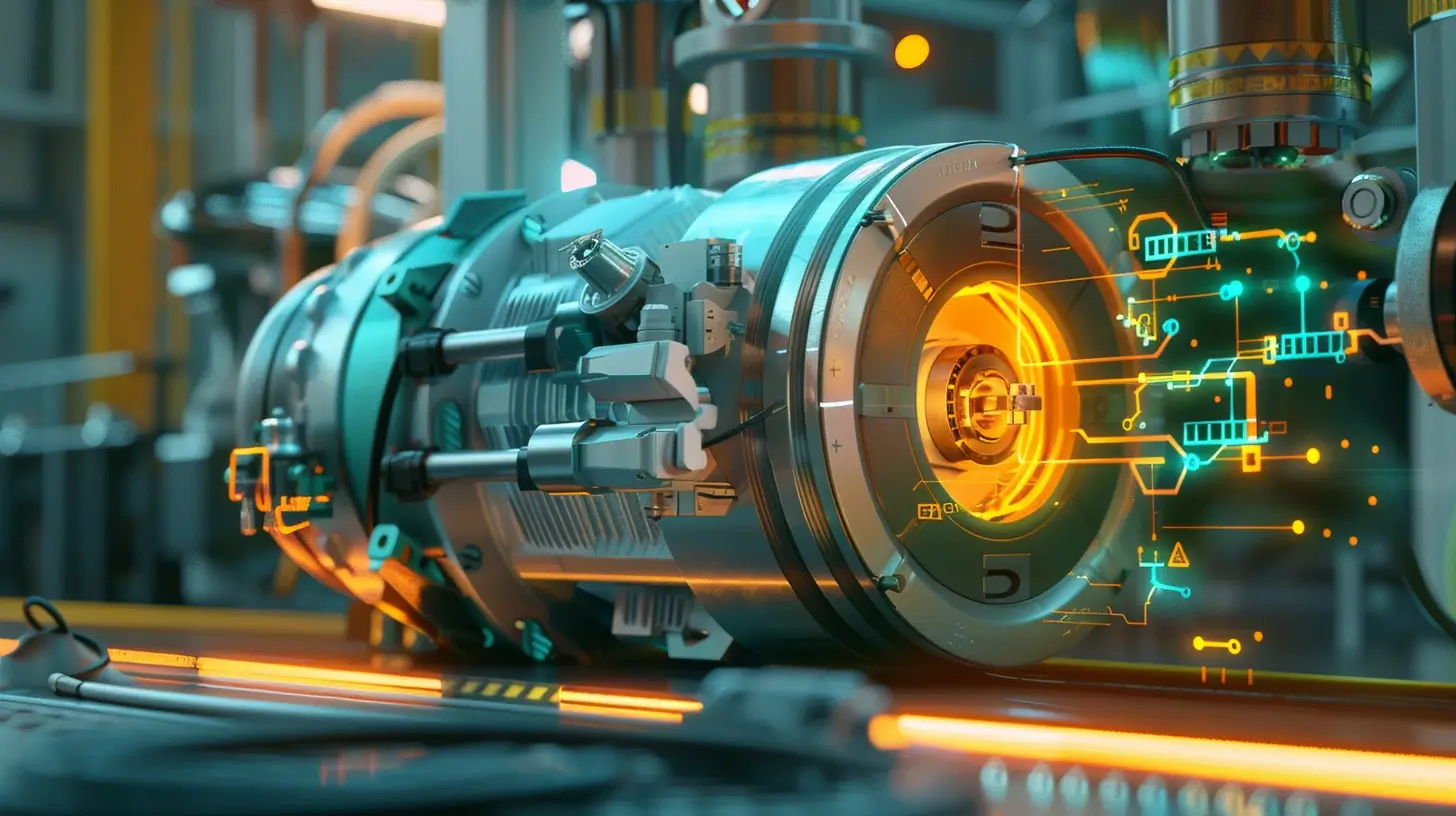

I recall the first time I integrated a motor with a variable frequency drive; it transformed how I approached motor control.

A motor and variable frequency drive package combines an electric motor with a VFD to provide precise control over speed and torque, enhancing efficiency and performance.

This combination opens up a world of possibilities.

What Are the Different Types of Variable Frequency Drives?

I've often explored the various VFDs available to find the best fit for my projects.

The main types of variable frequency drives are voltage-source inverters (VSI), current-source inverters (CSI), and pulse-width modulation (PWM) inverters.

Each type offers unique advantages.

)

Dive Deeper into VFD Types

Voltage-Source Inverters (VSI)1

These are widely used due to their simplicity.

- Features: Utilize a constant DC voltage source.

- Applications: Ideal for general-purpose motor control.

- Benefits: Simple design and cost-effective solutions.

Current-Source Inverters (CSI)2

I found CSIs useful in specific high-power scenarios.

- Features: Operate with a constant DC current source.

- Applications: Suitable for large motors requiring high power.

- Benefits: Excellent for regenerative braking systems.

Pulse-Width Modulation (PWM)3 Inverters

PWMs offer precise control, which I've leveraged in sensitive applications.

- Features: Control motor speed by adjusting the width of voltage pulses.

- Applications: Used where precise speed control is necessary.

- Benefits: High efficiency and reduced harmonic distortion.

Comparison Table

| Type | Features | Applications | Benefits |

|---|---|---|---|

| VSI | Constant DC voltage | General-purpose | Simple and cost-effective |

| CSI | Constant DC current | High-power motors | Good for regeneration |

| PWM | Adjusts pulse width | Precise control needs | Efficient and precise |

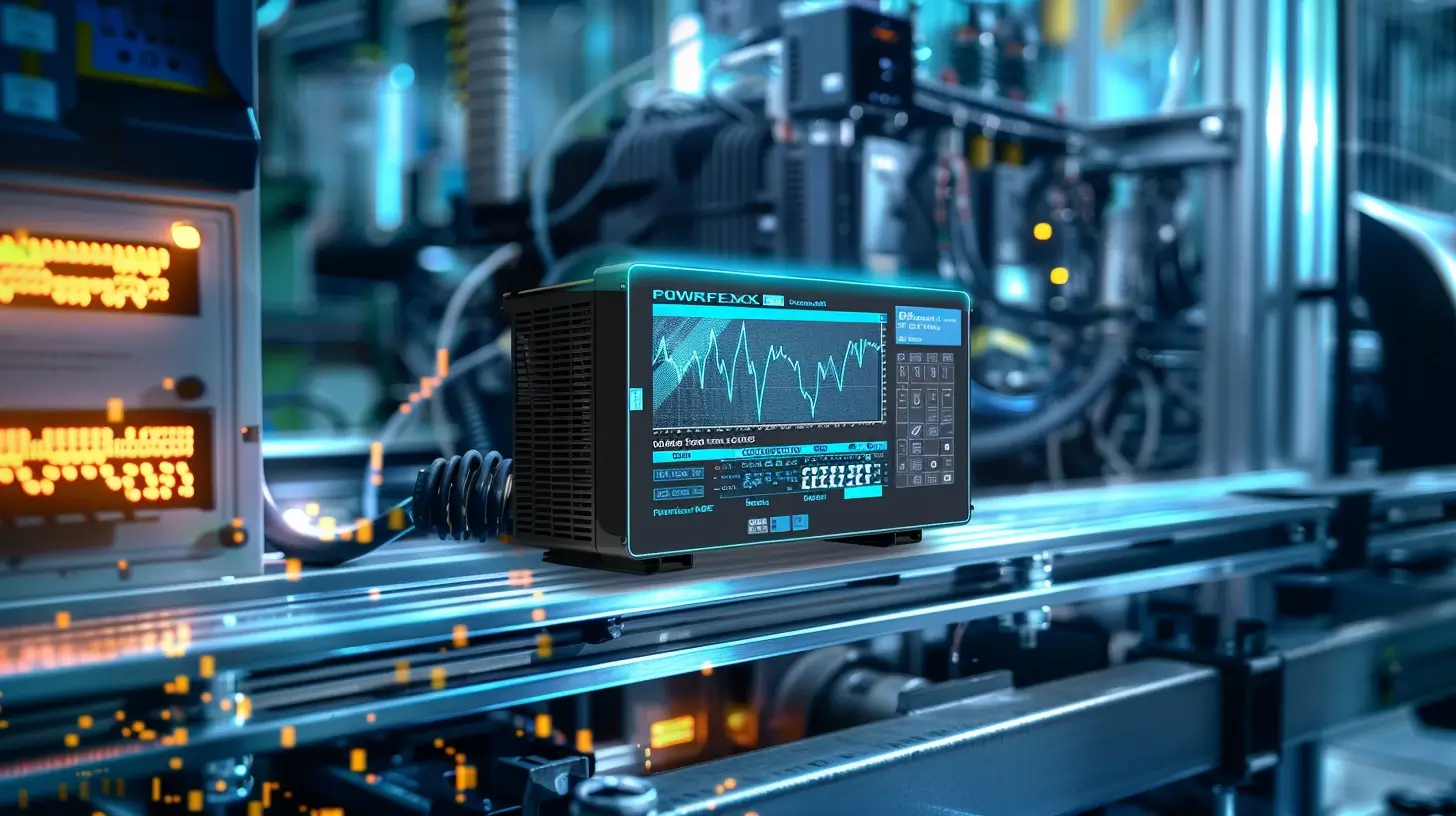

What Does a PowerFlex Drive Do?

I recently installed a PowerFlex drive and was impressed by its capabilities.

A PowerFlex drive4 is a type of VFD produced by Allen-Bradley that controls motor speed and torque with advanced features for industrial applications.

It's more than just a standard drive.

(

)

Dive Deeper into PowerFlex Drives

Advanced Control Features

- Smart Motor Control: Offers precise adjustments for optimal performance.

- Energy Savings: Built-in functions reduce energy consumption.

- Safety Options: Includes safety features that I've found invaluable.

Connectivity and Integration

- Communication Protocols: Supports Ethernet/IP, DeviceNet, and more.

- Easy Integration: Fits seamlessly into existing control systems.

- Remote Monitoring5: I've monitored systems remotely, enhancing efficiency.

Applications in Industry

- Manufacturing: Controls machinery like conveyors and mixers.

- Water Treatment: Regulates pumps and blowers.

- Mining: Manages heavy-duty equipment with reliability.

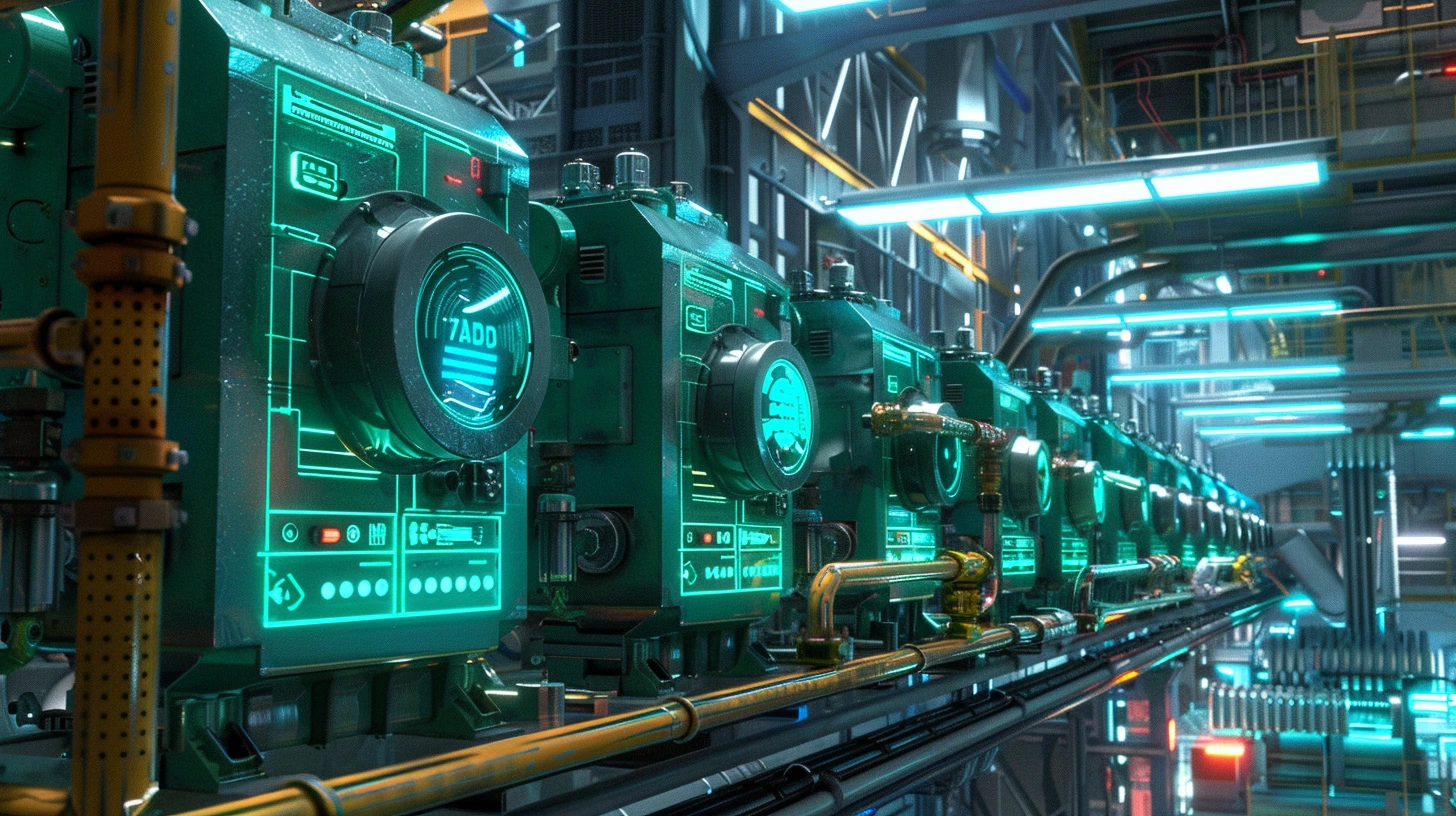

What Type of Motors Have Variable Frequency Drives Fitted?

This is a question I've delved into during my projects.

Variable frequency drives are commonly fitted to AC induction motors, but they're also used with synchronous and permanent magnet motors.

Choosing the right motor is crucial.

(

)

Dive Deeper into Motor Compatibility

AC Induction Motors6

- Why Use Them: They're robust and widely available.

- My Experience: I've found them reliable for most applications.

- Benefits: Cost-effective and suitable for variable speed control.

Synchronous Motors7

- Features: Operate at constant speeds synchronized with the supply frequency.

- When I Use Them: In applications requiring precise speed.

- Advantages: High efficiency and power factor correction.

Permanent Magnet Motors8

- Characteristics: Use permanent magnets in the rotor.

- Applications: Ideal for high-performance needs.

- Benefits: High efficiency and compact size.

Table of Motor Types

| Motor Type | Features | Benefits | Applications |

|---|---|---|---|

| AC Induction Motors | Simple and durable | Cost-effective | General industrial use |

| Synchronous Motors | Constant speed operation | High efficiency | Precision tasks |

| Permanent Magnet Motors | Permanent magnets in rotor | Compact and efficient | High-performance needs |

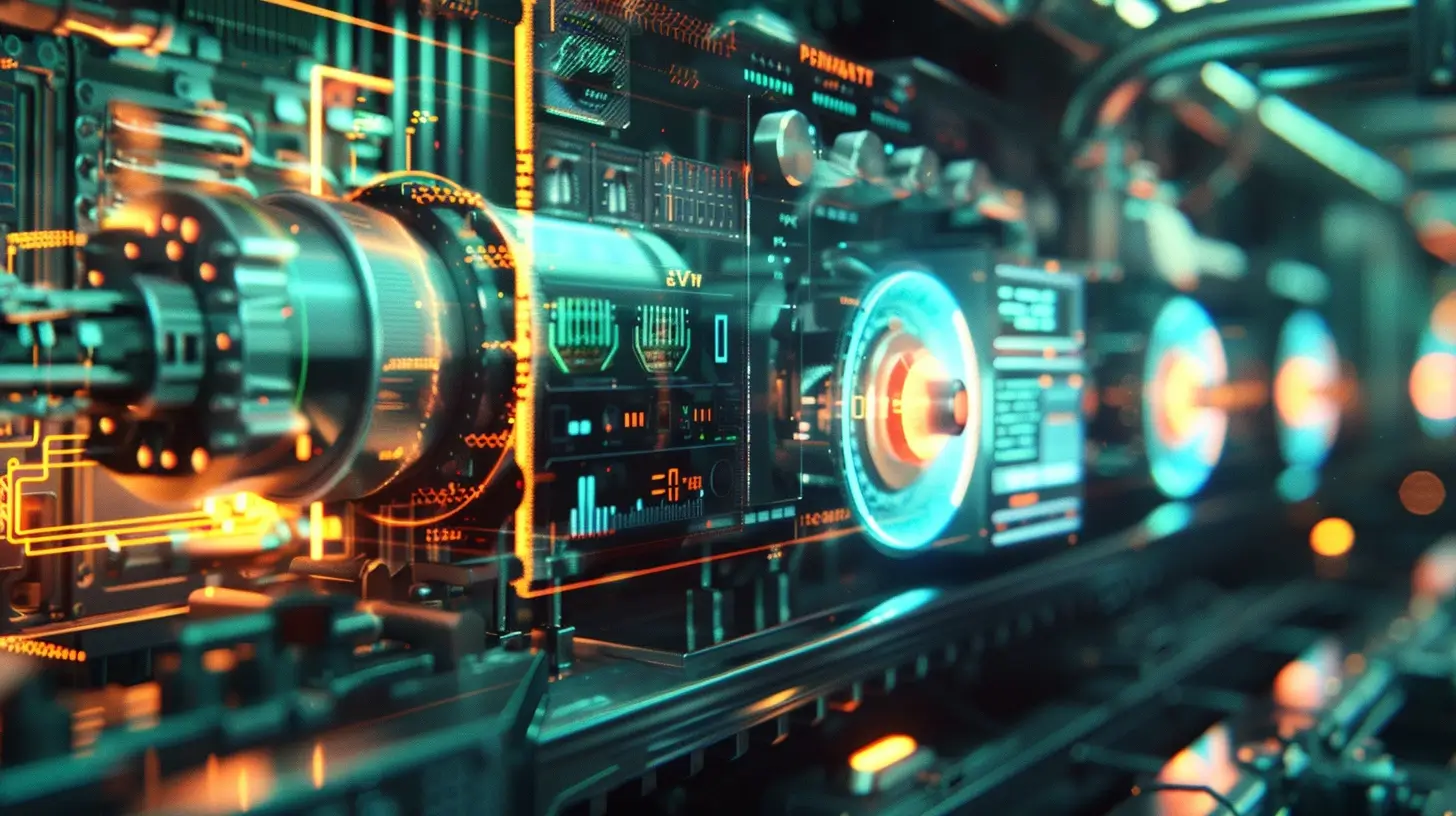

What Does a Variable Frequency Drive Do?

Understanding this was key in many of my projects.

A variable frequency drive controls an electric motor's speed and torque by varying the frequency and voltage of its power supply.

It's essential for modern motor control.

(

)

Dive Deeper into VFD Functionality

How VFDs Work

- Rectification9: Convert incoming AC power to DC.

- Inversion: Change DC back to AC with adjustable frequency.

- Control: Adjust frequency and voltage to control motor speed.

Benefits I've Observed

- Energy Efficiency10: Significant reductions in power usage.

- Process Optimization: Fine-tune operations for better results.

- Extended Equipment Life: Less mechanical stress means longer life.

Applications I've Worked On

- HVAC Systems: Optimizing fan and pump speeds.

- Manufacturing Equipment: Improving conveyor belt control.

- Renewable Energy Systems: Enhancing solar pump performance.

Conclusion

Understanding motor and variable frequency drive packages has transformed how I approach efficiency and control in my projects.

-

This link explains how VSI works in motor control systems, focusing on its simplicity and common applications. ↩

-

Describes the role of CSI in VFDs, highlighting its use in high-power systems and regenerative braking. ↩

-

Introduces PWM technology, its working principles, and its role in achieving high efficiency and reduced harmonic distortion. ↩

-

Explains the features, benefits, and industrial applications of PowerFlex drives. ↩

-

Provides insights into how remote monitoring enhances system efficiency and reliability. ↩

-

Explains the advantages of pairing AC induction motors with VFDs, including durability and cost-effectiveness. ↩

-

Highlights the features of synchronous motors, emphasizing their high efficiency and precision. ↩

-

Discusses the efficiency and compact design of permanent magnet motors, which make them ideal for high-performance applications. ↩

-

Explains how rectification works in VFDs and its importance for motor speed control. ↩

-

Highlights the role of VFDs in optimizing energy consumption by adjusting motor speeds. ↩