(

)

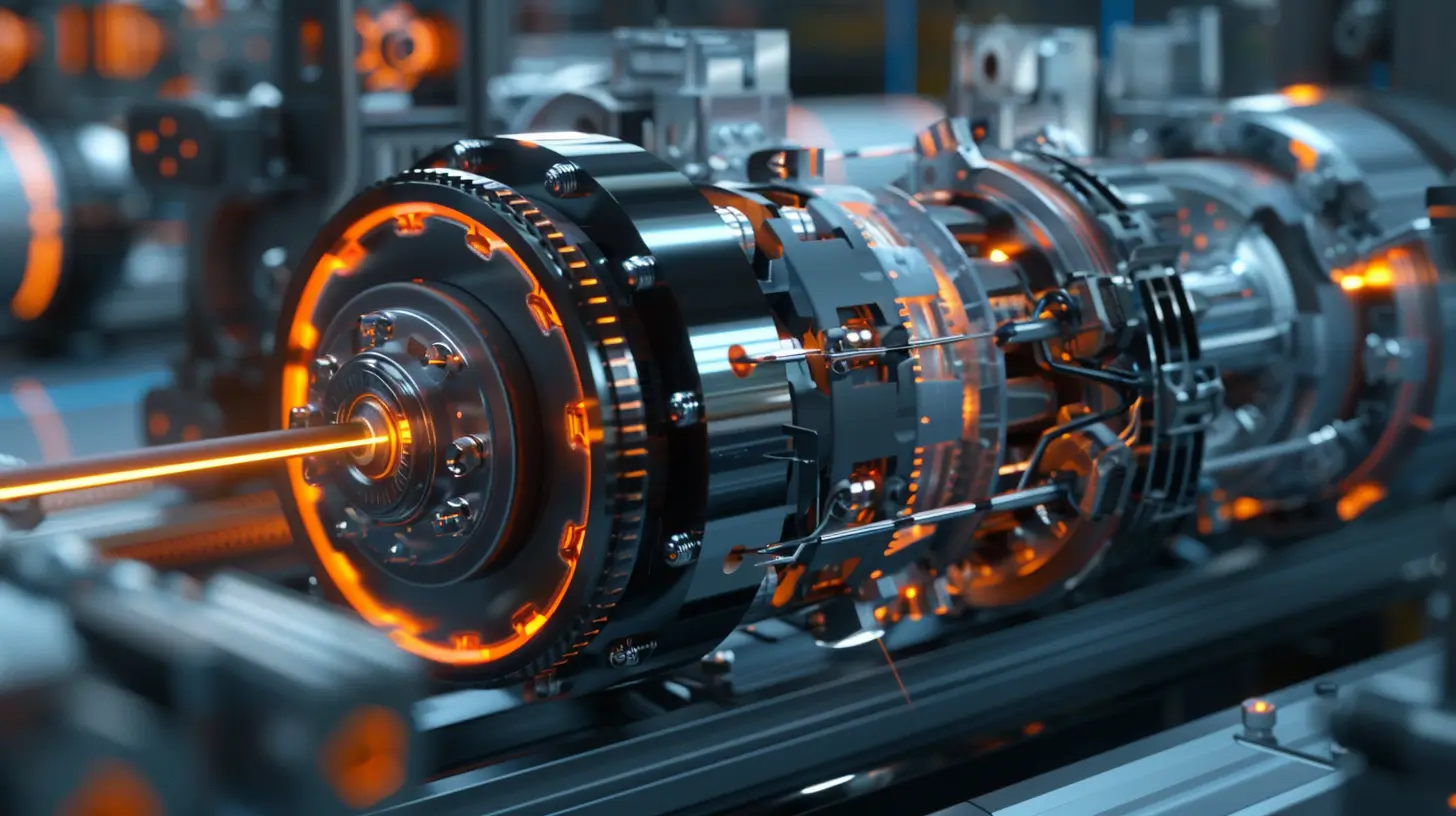

A variable frequency drive (VFD) is a game-changer in industrial control systems. It adjusts motor speed and torque, offering energy savings and smoother operations. But how does it work? Let's dive into this technology and its benefits.

A variable frequency drive (VFD) controls the speed of an electric motor by adjusting the frequency of the electrical power supplied to it. This results in energy savings, improved performance, and greater flexibility in motor-driven systems.

But what makes a VFD so crucial in modern industries? To understand its importance, we need to break down how it works, what it can do, and why it's become a staple in automation and control systems.

Which is suitable for variable frequency drive?

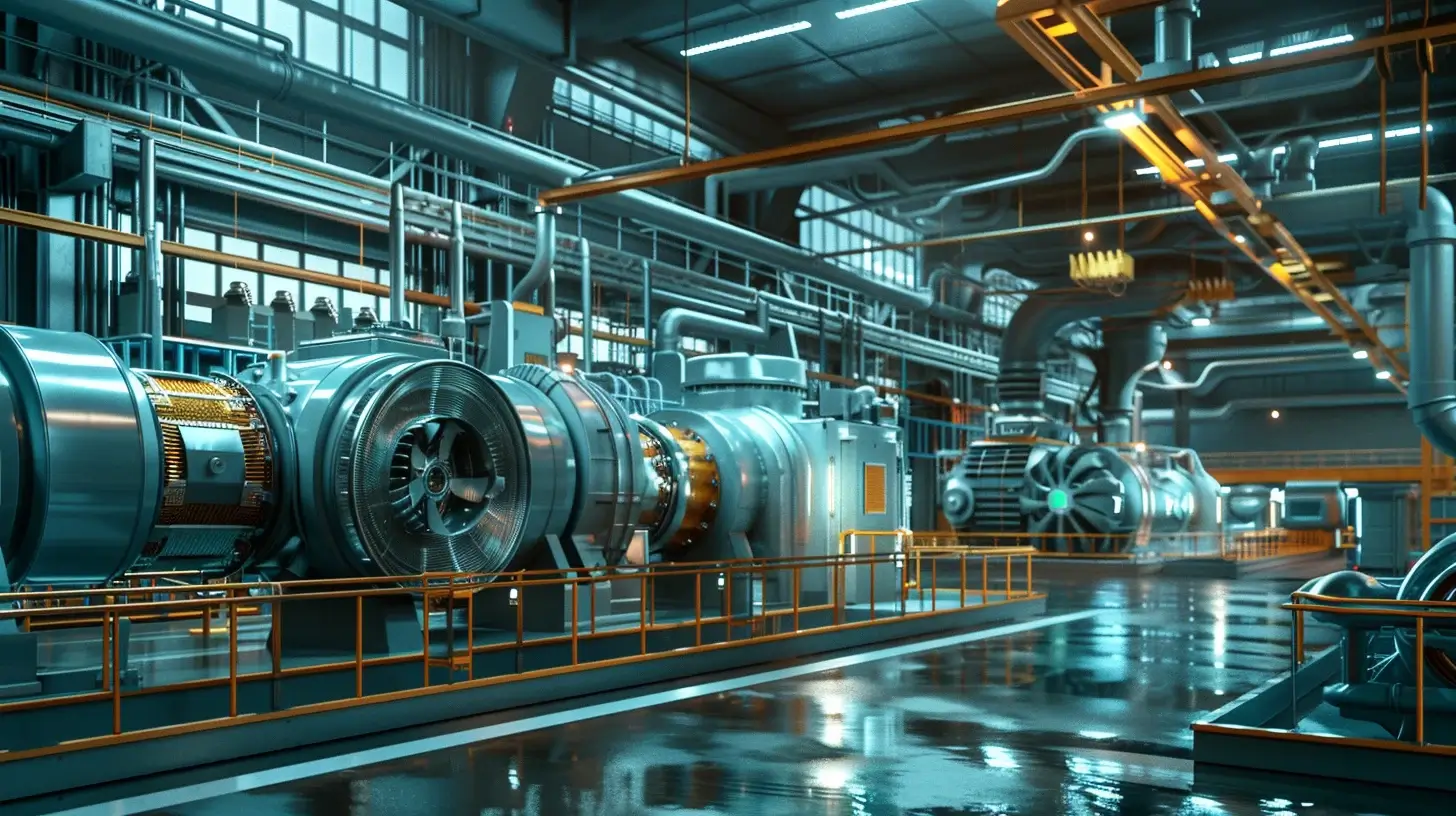

Not all systems are a perfect match for VFDs. But certain industries and applications see significant benefits from using them. Let’s take a closer look at where VFDs really shine.

VFDs are best suited for systems where load demands vary. This includes applications like HVAC1, [water pumps]2(https://www.callaghanpump.com/blogs/vfd-pumps-a-simple-guide-to-their-uses-and-benefits/ "water pumps"), and conveyor systems, where adjusting motor speed can improve energy efficiency and overall system performance.

(

)

Ideal Industries for VFD Use

| Industry | Application Example | Benefit of VFD |

|---|---|---|

| HVAC Systems | Fans, air handling units | Energy savings by adjusting fan speeds based on demand |

| Water Pumps | Pumps in water treatment facilities | Adjust pump speeds for variable flow rates, reducing energy consumption |

| Conveyor Systems | Conveyor belts in manufacturing | Precise control of speed to match production needs, reducing waste |

Why VFDs Excel in These Applications

In industries like HVAC, water management, and manufacturing, systems often don’t need to run at full speed all the time. A VFD helps by adjusting motor speed based on real-time demand. This reduces energy waste, increases system longevity, and improves process control. For example, in HVAC systems, adjusting fan speeds to match airflow requirements ensures that energy isn’t wasted when demand is low.

What is a VFD for dummies?

The term "VFD" might sound technical, but in reality, it’s a fairly simple concept. Let’s break it down in the most straightforward way possible.

A VFD is simply a device that controls the speed of an electric motor by changing the frequency of the electricity supplied to it. In simpler terms, it allows the motor to speed up or slow down depending on what’s needed for the job.

Simple Example: Fans and Pumps

Imagine you’re in a large factory with a fan running. If the fan runs at full speed all the time, it can waste a lot of energy, especially when it doesn’t need to. With a VFD, you can adjust the speed of the fan based on the actual cooling needs. The same goes for water pumps in industrial applications. By controlling the speed of the pump, a VFD ensures that the motor only uses the energy necessary for the task at hand.

How VFDs Help in Real Life

Let’s take a typical example: In a water treatment facility, the amount of water that needs to be pumped changes throughout the day. Instead of running the pumps at full speed all the time, which wastes energy, a VFD adjusts the speed to match the required flow, thus saving on electricity and reducing wear on the equipment.

What is a PowerFlex drive?

PowerFlex drives are one of the most popular types of VFDs used in industrial applications today. But what makes them different from other VFDs?

PowerFlex drives3, developed by Rockwell Automation, are designed to offer advanced motor control for a variety of applications. Known for their versatility, reliability, and ease of integration, PowerFlex drives are widely used in industries like manufacturing, energy, and automation.

PowerFlex Features

| Feature | Description | Benefit |

|---|---|---|

| Advanced Control Capabilities | Control over motor speed, torque, and position | Provides precise control for complex operations |

| Flexible Integration | Works with a variety of [automation systems ] | Easily integrates into existing setups |

| Built for Harsh Environments4 | Rugged design for tough industrial conditions | Ideal for demanding industries like mining or oil & gas |

Why Choose PowerFlex VFDs?

PowerFlex drives are chosen for their flexibility, performance, and reliability in demanding industrial environments. Their advanced motor control and ability to integrate with various automation systems help businesses improve efficiency, reduce downtime, and maximize the lifespan of their equipment. Additionally, PowerFlex offers a range of models tailored to different motor types, ensuring that you get the right solution for your specific application.

Conclusion

In summary, a variable frequency drive (VFD) is an essential tool for improving energy efficiency and [motor control]5(https://www.teledynelecroy.com/static-dynamic-complete?utm_source=google&utm_medium=ppc&utm_campaign=motor+drive+analyzer&utm_term=vfd%20analysis&gad_source=1&gclid=CjwKCAiAxqC6BhBcEiwAlXp45wpLjjg-UI--un4C-YTVx3EmPsUu4ZSMB7c8YqNgfRdXi7MKz9cFuxoCwn0QAvD_BwE "motor control") across various industries. By understanding how VFDs work and selecting the right one for your application, you can achieve better performance, save energy, and enhance system reliability. Whether you choose a general VFD or a specialized model like PowerFlex, it’s clear that these devices are vital to modern industrial operations.

-

This resource helps readers understand how VFDs reduce energy consumption in HVAC systems by adjusting fan speeds according to demand, improving overall system efficiency. ↩

-

Clicking this link will show how VFDs help optimize water pump operations by adjusting flow rates, resulting in energy savings and reducing wear on the pumps. ↩

-

Clicking this link will provide an in-depth explanation of PowerFlex drives, including their features, applications, and why they are widely used in industries for advanced motor control and efficiency improvements. ↩

-

Clicking this link will explain how PowerFlex drives are specifically designed for rugged industrial conditions, making them ideal for applications in demanding industries like mining and oil & gas. ↩

-

This link provides insights into advanced motor control systems, explaining how technologies like VFDs enhance efficiency, performance, and longevity in industrial motor applications. ↩